Machine Demo: MW35 with iFLiPP - Faster Functionality Meets Furious Productivity

MW35's lightning-fast loading and unloading pace of three seconds is enhanced by the patented iFLiPP automated orientation feature, eliminating changeovers and machine downtime. (Sponsored)

Share

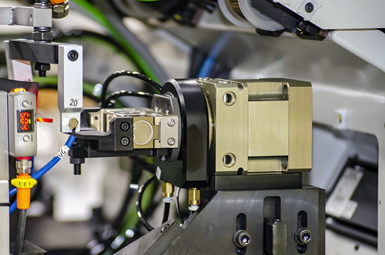

Muratec Machinery USA's MW35 twin-spindle machine with pick and place iFLiPP loading system enables quick materials loading for continuous operation and mass production. MW35's lightning-fast loading and unloading pace of three seconds is enhanced by the patented iFLiPP automated orientation feature, which feeds the workpiece into its swing arm—either head-leading or head-trailing—in 1.9 seconds, eliminating changeovers and machine downtime.

Muratec will be at IMTS in the south building, level three, in booth #338844.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.