Tooling

Latest Tooling News And Updates

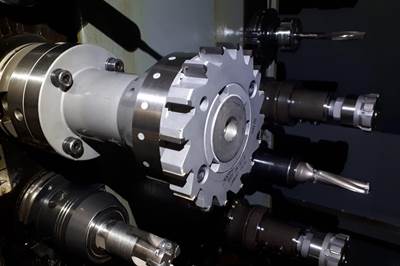

Iscar Quick-Change System Boosts Machining Stability

PMTS 2025: The NeoSwiss modular quick-change system’s clamping mechanism provides high repeatability, maintaining a position accuracy of ±0.0008" during head replacements.

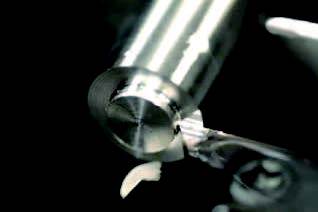

Read MoreANCA Software Monitors Thermal Growth in Tap Production

Motor Temperature Control removes fluctuations caused by thermal growth, providing greater precision and consistency in tap production.

Read MoreSPC Innovations Milling Attachments Boost Productivity

PMTS 2025: SPC Innovations Inc. showcases multispindle attachments that can increase productivity, reduce secondary operations and enable for quick job changeovers.

Read MoreMonaghan Drills Features Optimized Chip Evacuation

The R4 Speed Drill Series features a two-flute geometry that provides optimal stability and reduces cutting forces.

Read MoreHorn Broaching System Streamlines Production Operations

PMTS 2025: The AR15 magwell broaching system enables manufacturers to achieve precise broaching directly within the CNC cycle, eliminating the need for a dedicated vertical broaching machine.

Read MorePlatinum Toolholding System Enables Quick Changeovers

The U-Tec changing system enables a standard ER output live tool to accept various adapters for different applications, enabling quick changeover of tools on almost any lathe or mill using a single tool.

WatchFeatured Posts

Picking the Right End Mill

Kennametal global product manager Katie Myers explains how cutting tool features can impact machining strategies for different materials.

Read MoreInside the Process of Cutting Tool Recycling

Global Tungsten & Powders, part of the Ceratizit Group, sheds light on the processing steps that convert a shop’s used inserts into new tools and other applications.

Read MoreIndexable Drill Heads Double Profitability

Moving to a robust line of indexable drills enabled this shop to dramatically alter the manufacturing process for a problem part, doubling its profitability.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MorePowRgrip Responds to Three Tooling Trends

Rego-Fix’s PowRgrip tooling system has expanded over the past 20 years to incorporate a wider range of tool sizes, as well as automation.

Read MoreAdvanced CAMs Simplify Programming of Conical Barrel Cutters

Conical barrel cutters have grown in popularity thanks to the large stepovers that reduce the time needed for some finishing processes, but advanced CAM systems can dramatically improve their usefulness.

Read More

.jpg;maxWidth=300;quality=90)